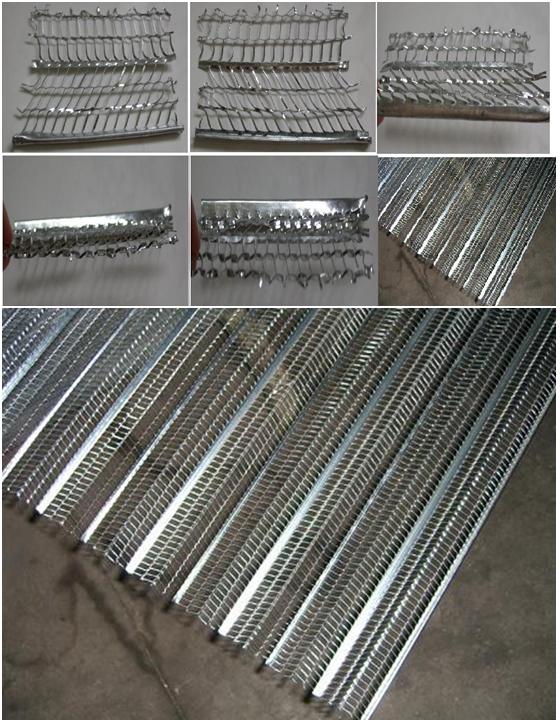

Rib Lath (Template Network), Rib Lath (3/8" High Rib) etc, galvanized rib lath is widely used as a background for plaster, render, stucco application in construction of suspended ceilings partition. Please contact with me if you interested in our rib lath products.

Shortening the Time (of construction)

- Easy to handle due to the light-weighted subsidiary materials (i.e. 1/10 weight of plywood)

- Improve the work efficiency

- Easy to dismantle

- Quick refilling-up

Cost Efficiency

- No skillful hand needed

- Cost savings of handling the form dismantling, disused materials and storage management

- Easy to work with

- Easy to bend into round form or right-angled side

- Curved surface

Minimizing the Space to install

- 1/20 of plywood in size

- Minimizing the storage space of material at the site

- Minimizing the cost of material handling

Excellence of Finished-work (plastering and tiling)

- Strengthening the level of adhesion through wire-net of skeleton surface

- Preventing the crack of plastering surface

- No prime plastering required

Quality Improvement of Concrete

- Easy to inspect the layout of reinforcing steel and easy to clean

- Ensuring homogeneous concrete strength(upper and lower parts)

- Restraining the surface crack

- Easy to strengthen the connection parts

- Improved earthquake-proof performance

Reduction of Wasted materials

- Nearly none of wastes after construction

- Easy clear and clean the site

Compatible with existing forms

- Plywood cast

- Euro-Form

Prevention of unreliable work

- Visibility of installation

- Preventing the quality deterioration by eliminating the surplus water

Improving the site safety

- Easy of handling with safety through the light-weight

- Excellent work results on the limited work space

Rib Lath Product parameters

| 1. SW×LW=Size of opening R.H=Rib Height R.D=Rib Distance M.T= Material Weight | |||||

| SW×LW/mm | M.T/mm | R.H.mm | R.D./mm | Wt kg/m2 | Sheet size |

| 4.5×15 | 0.3 | 4 | 75 | 1.26 | 610/750×2440 |

| 4.5×15 | 0.35 | 4 | 75 | 1.47 | 610/750×2440 |

| 4.5×15 | 0.4 | 4 | 75 | 1.68 | 610/750×2440 |

| 4.5×15 | 0.45 | 4 | 75 | 1.89 | 610/750×2440 |

| 4.5×15 | 0.5 | 4 | 75 | 2.10 | 610/750×2440 |

| 2. SW×LW=Size of opening R.H=Rib Height R.D=Rib Distance M.T= Material Weight | |||||

| SW×LW/mm | M.T/mm | R.H.mm | R.D./mm | Wt kg/m2 | Sheet size |

| 4.5×15 | 0.3 | 8 | 150 | 1.25 | 610×2440 |

| 4.5×15 | 0.35 | 8 | 150 | 1.46 | 610×2440 |

| 4.5×15 | 0.4 | 8 | 150 | 1.67 | 610×2440 |

| 4.5×15 | 0.45 | 8 | 150 | 1.88 | 610×2440 |

| 4.5×15 | 0.5 | 8 | 150 | 2.09 | 610×2440 |

| 3. SW×LW=Size of opening R.H=Rib Height R.D=Rib Distance M.T= Material Weight | |||||

| SW×LW/mm | M.T/mm | R.H.mm | R.D./mm | Wt kg/m2 | Sheet size |

| 10×17 | 0.3 | 8 | 75 | 1.06 | 610×2440 |

| 10×17 | 0.35 | 8 | 75 | 1.23 | 610×2440 |

| 10×17 | 0.4 | 8 | 75 | 1.41 | 610×2440 |

| 10×17 | 0.45 | 8 | 75 | 1.59 | 610×2440 |

| 10×17 | 0.5 | 8 | 75 | 1.76 | 610×2440 |